Tech Tip: Brake Hoses

/Old (bottom) vs New (top) brake hose

During the restoration of our car, we've had to replace more a few components that are no longer available. One of the main goals that I've had when sourcing replacement parts is to maintain the look of the original component while replacing it with one that is functionally superior. Case in point, the flexible front brake hoses. We are fortunate to have the original hoses and I wanted to use original style fittings, while upgrading to stainless steel flex hoses. The problem is that the modern stainless hoses look too modern. Also, where could I get fittings that had the same basic ends as the original?

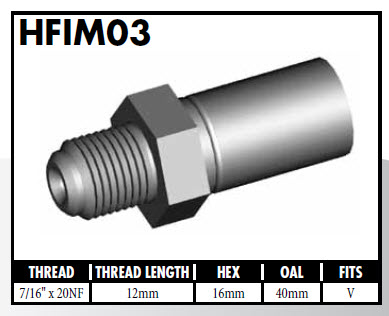

First off, we should all be grateful for the Internet. I'm a firm believer that the Internet is solely responsible for the increase in quality of automotive restorations. After a few minutes of searching, I stumbled across the BrakeQuip Dealer Catalog. Armed with my original hoses, I measured the fittings and found the following BrakeQuip equivalent fittings:

Unfortunately they aren't brass, but these steel fittings are much stonger.

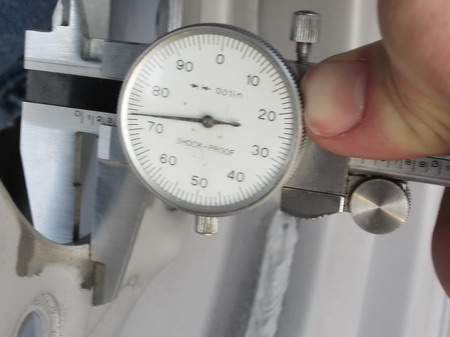

Next step was to find a suitable stainless steel braided brake hoses. I didn't want the typical stainless steel color as it just screamed modern...I was looking for something black, ideally with a matte finish. I found that black lines were available, but the outer coating was shiny. Then I had an idea...fabric wire loom covers look a lot like the original brake hose material...what if I bought some of that and slipped it over the stainless steel brake hoses while they were being fabricated. I found a 7' length of PICO 3/8" (ID) fabric loom (with asphalt coating) on Amazon that looked just like our old brake hoses.

Armed with my fabric loom hose, I went to our local ParkerStore and explained what I wanted. After convincing them I wasn't crazy, they agreed to make up the hoses to meet my requirements. They used their "smoke" colored stainless hoses, the fittings noted above, my PICO fabric loom, and put them together with a total length of 17.5". As you can see, they came out pretty good with a total cost of around $40 per line, less if you have a business account with Parker.

Detail: Old vs New

The outer wire loom housing pulled back to reveal the braided stainless hose within