Allard J2X LeMans 3149

/-Charles Warnes

In 2013 we (Colin and I) wrote a piece in the Allard Register entitled “Never Again!” – Confessions of a ‘Barn Find’ Junkie.” We concluded that story with us trading our Hemi-powered Allard K3 for an engineless, basket-case J2X Le Mans. Our stated goal was to get it on the road some time over the next few years. Now, ten years later, we want to give you an update and some back story.

Our K3 project had stretched out 22 years for a number of reasons. We started in the pre-internet days, when the worldwide search for Allard parts was a complex and time-consuming endeavor. Financial constraints also played a role, and we were sometimes ‘guilty’ of allowing career and family commitments to take priority. Colin and I had a lot of time and effort invested in our K3, we enjoyed driving it, and had no plans on ever parting with it … until we stumbled across this J2X Le Mans.

The early months of 1952 were a challenging time for the Allard Company. Their upper management (Sydney Allard, Tom Lush and Guy Warburton) was heavily focused on the planning, reconnaissance and testing two Monte Carlo Rally entrants; and Allard’s engineering department was quite involved in developing the all new, envelope-bodied JR model for 1953.

Allard ran in the 24 Hours of Le Mans in 1950 and ’51, and they planned to run two J2X’s in 1952. But in January FIA announced that the new envelope body rules would go into effect in 1952 rather than 1953. Thus, Allard’s JR project had to be sidelined so that two J2X’s could be modified in time to run at Le Mans.

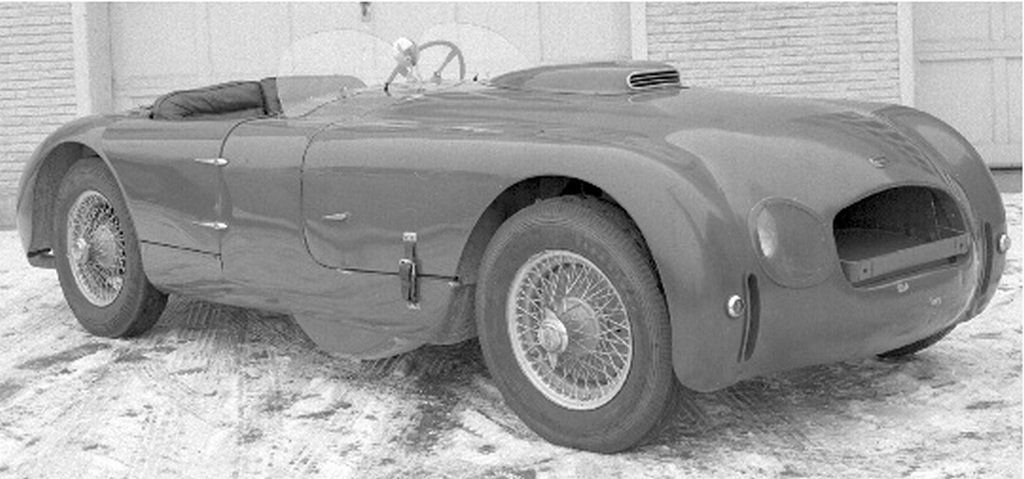

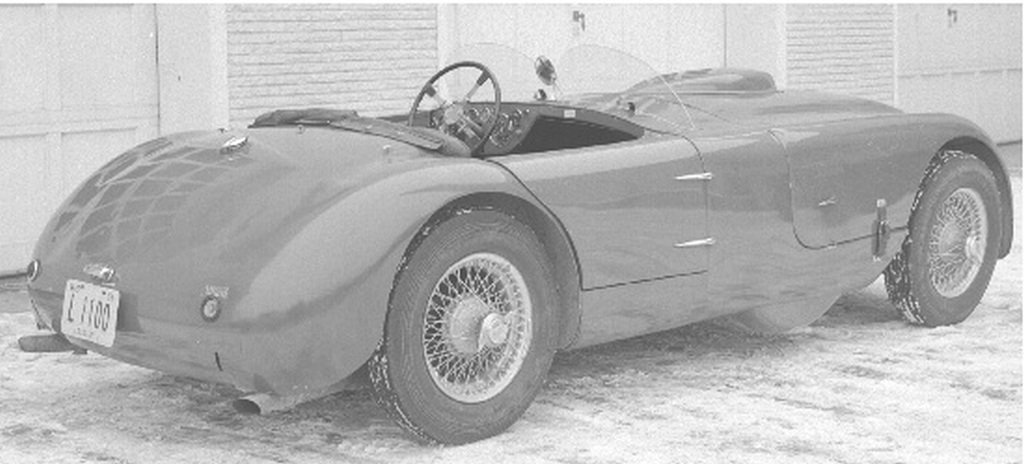

The Le Mans bodied J2X was basically a standard Allard J2X with the same ladder frame, suspension, running gear and rear body shell. The front of the body from the door jams forward, was all new. The cowl bore a striking resemblance to a Jaguar C-Type, with the whole bonnet hinged at the front. When closed, the bonnet matched up with two lower pods that extended back to the rear wings. Those pods and the cowl were all one complex structure that, through a variety of body fixtures, was ‘married’ to the chassis frame. The curvaceous doors were unique to the J2X LM.

After the 1952 Le Mans, Allard built eleven more Le Mans bodied J2X’s – ten of which were exported to various regions of the US. Two of them went to Noel Kirk Motors in Los Angeles, where one was fitted with a Chrysler hemi, and one with Cadillac power.

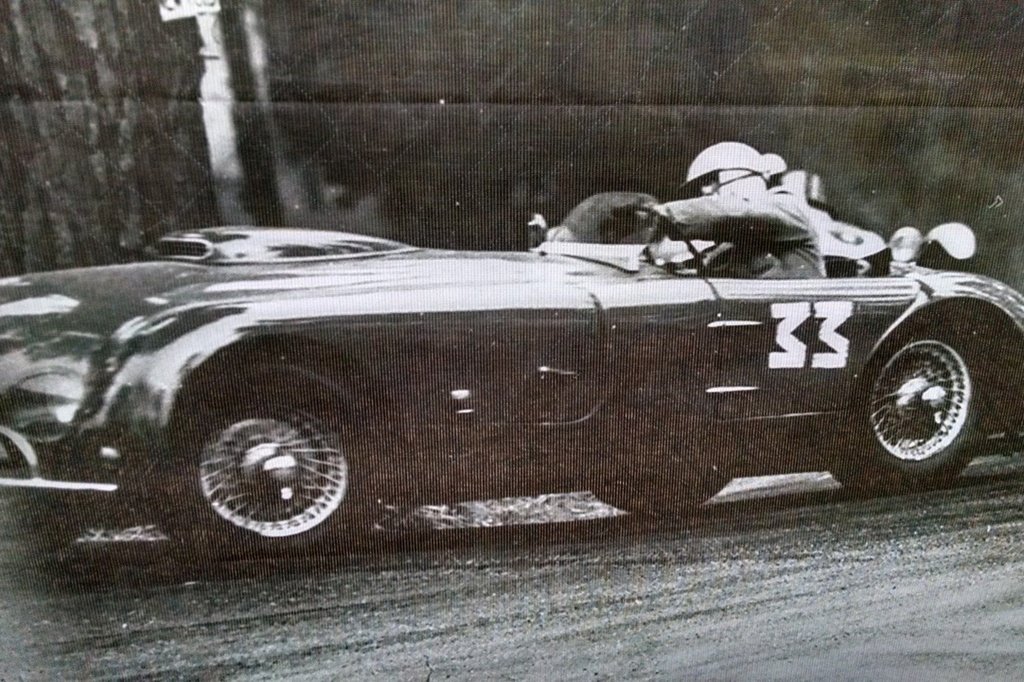

The biscuit-colored Cad Allard was sold to George Sawyer, who raced it in various California venues during the ’53 season. (Coincidentally, I met Mr. Sawyer in 1999, at which time he told me that he had owned and raced an Allard J2X Le Mans back in the early ‘50’s. Who would have known that 14 years later we would own that very car.)

#3149 suffered some accident damage during the ’53 season, and got repainted to red with silver wheels. George sold the car to Dr. Frank Hodges, who raced it at Pebble Beach in ’54. Dr. Hodges then sold the car to Daniel Parker, owner of the Parker Pen Company.

As publishers of the Allard Register, Colin and I sometimes get inquiries from Allard enthusiasts and previous Allard owners. Like a 2013 email from Geoff Parker inquiring about a Cad-powered J2X Le Mans that was once owned by his father, Dan Parker. He said that Dan bought the car used in California, and he and his mother drove it back to their home in Janesville Wisconsin. Once there he raced the car in some regional SCCA races. Geoff inquired if we might be able to help him with information about the history, and possibly the location, of that car. It was an easy question for us, for we informed him of the car’s precise location – in our garage.

Subsequent owners were Jerry Dunbar in Illinois, and Jack Brownell of Milwaukee Wisconsin. Jack raced it at a few courses around the Midwest before the car suffered some race and vandalism damage. Jack then sold it to his brother Paul for $350, who kept it in storage for the next 52 years.

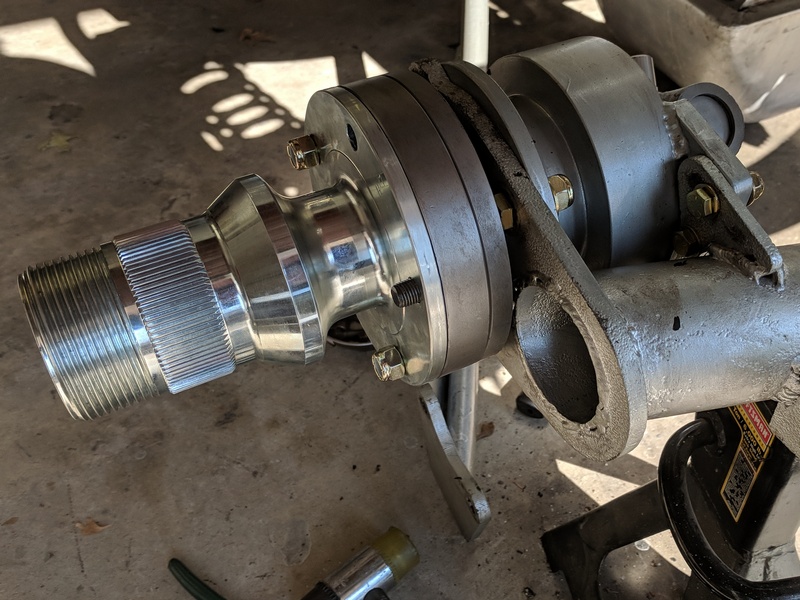

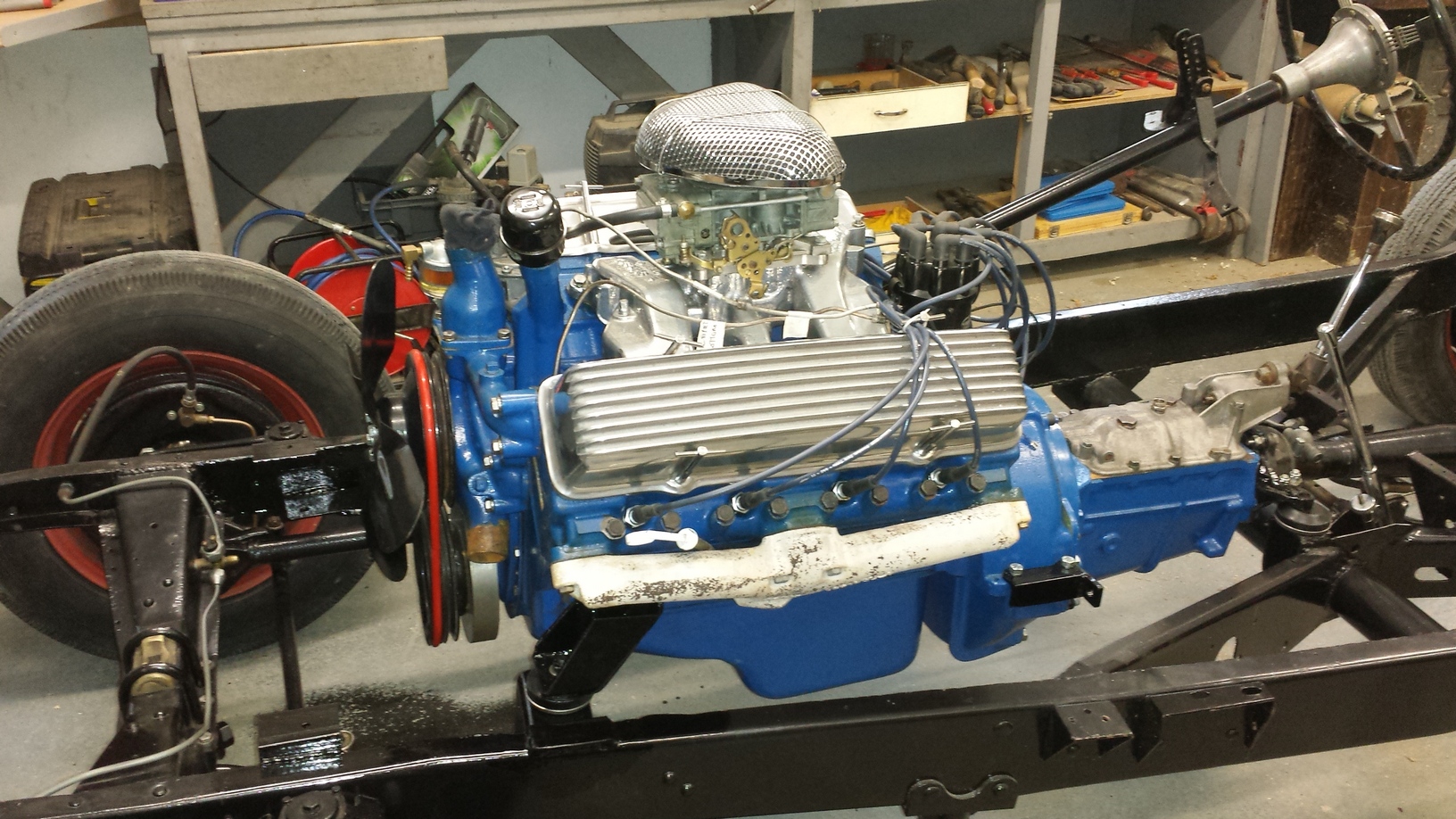

Our goal was to refurbish #3149 in the spirit of the post-war era, but with safety enhancements along the routes taken by restoration shops and racers. We rebuilt a mildly modified Cad engine which we matched to a wide-ratio 4-speed Borg-Warner T-10, a fuel cell, and a dual channel brake system. The differential had been modified for an open drive shaft some 60 years earlier, and we had it rebuilt with a 3.25 final ratio.

We wanted it to be a solid, safe and fun car to drive rather than a concours show car. We are not professional mechanics or coach builders - just couple guys who do a lot of our own work. We pursued a degree of finish that would deserve the respect of our peers – whether it be the local Fresno car scene or fellow Allard owners. The body bears a considerable amount of historic patina from this car’s racing days, and for now we choose to use and display it with the bare aluminum. We get a lot of positive feedback encouraging us to keep it that way.